In this post, we sit down with Scott Wilisky of STW Cutting Edge Carpentry INC. to talk about a unique, beautiful, yet often overlooked flooring finish — polished concrete. Scott’s portfolio of high-end custom homes is scattered throughout British Columbia’s Rocky Mountain range, and quite a few of his projects feature this exceptional finish.

Today, Scott explains the pros and cons of polished concrete floors and shows us the easiest way to get the job done.

The Advantages of Polished Concrete

The primary reason for choosing to polish your concrete slab, whether it be your basement slab or your slab-on-grade, is that it’s simple and cost-effective, Scott says.

Unlike the process behind installing finishes like vinyl, hardwood, or carpet, polishing a concrete slab is quick, straightforward, and an easy way to trim construction costs.

But as Scott points out, there’s more to polished concrete than simplicity and low costs. These floors do look incredible. Their aesthetics are unique, and contrary to popular belief, don’t necessarily smack of industrial space. On the contrary — even with concrete’s natural color, this type of floor can lend a space as much stylish decor and coziness as any hardwood.

What’s more, polished concrete floors are non-porous, and unlike tile or hardwood, they don’t accumulate dirt in their crevices; this makes cleaning them a breeze. As you can see, this type of floor is relatively low maintenance.

Last but not least, Scott says that polished concrete floors are the ideal solution because that is in fact the finish and there is no need for the expense of an additional floor covering.

Why Polished Concrete Floors May Not Be for Everyone

The primary drawback of polished concrete floors is that they’re hard. Many folks out there prefer soft, comfy floors to walk on, so concrete is not the ideal flooring finish for everybody.

Plus, it may be best to protect polished concrete around entryways, as salt that gets in during wintertime may cause spalling in the concrete down the road.

That’s why it’s essential to present all the pros and cons of polished concrete to your buyers, so they can make an informed decision.

Radiant Flooring Is a Must for Polished Concrete Floors

Apart from being hard — which isn’t something anyone can fix, short of laying down a rug — polished concrete floors can also be cold. Luckily, they don’t have to be.

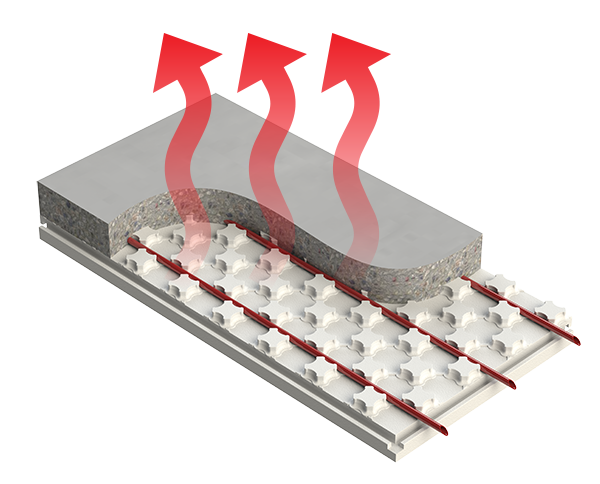

Radiant heat flooring offers a simple, comfy, energy-efficient way to heat concrete slabs. So, if you’re opting for polished concrete in homes you build, consider at least roughing in a radiant floor heating system.

All you have to do is lay down an insulation product and install the PEX tubing before you pour the concrete slab.

Using a special radiant floor heating panel like Heat-Sheet will make this process a breeze, as your crews will be able to simply walk the tubes in place instead of stapling them down.

How to Polish a Concrete Slab

We asked Scott to outline the polishing process for us, and he made it sound easy.

But the truth is — polishing concrete is a straightforward job.

Concrete — Nothing Unique About the Mix

That’s right — the regular old 25MPa mix will do just fine. As we mentioned above, it’s always good practice to rough in radiant tubing on top of a panel like Heat-Sheet.

Polishing — No Extra Major Costs

You’ll have to start polishing as the slab is poured. In this case, no acid treatment is required (as would be for an existing slab). All you have to do is power trowel. As a ballpark, Scott recommends budgeting for 4 hours of power troweling for every 1,500 ft2 of concrete, which would add roughly $400 to the cost of the slab.

Color — Goes Right into the Ready Mix

You add the color powder pouch into the ready mix before you pour. Unlike polishing, coloring is a costlier upgrade — coloring a 1,500ft2 slab will set you back approximately $1,500.

One thing to note here, integral color can remove air from the top of the concrete slab, potentially undermining the concrete’s integrity. Some integral color additives can also be affected by ultraviolet light; so, it’s always best to raise these points with the manufacturer before adding the color powder to the mix.

Sealer — Goes on After 30 Days

30 days after the pour, you can apply the sealer to your polished concrete surface. If you did rough in radiant heat, it’s vital to heat the slab to the standard heating level when sealing the slab. Sealing the same 1,500 ft2 slab we’ve been using as our example will set you back around $500.

Wrapping It Up

Polished concrete is about the easiest flooring out there, both for you and your future occupant. Installation is relatively straightforward and inexpensive, adding roughly only $900 to the cost of a 1,500ft2 slab (if you’re not adding color).

For your buyer, polished concrete offers a unique-looking finish that’s very easy to clean and maintain in good condition — unlike hardwood, tile, or carpet.

And while basement slabs tend to get uncomfortably cold, a radiant heat flooring system provides a handy, energy-efficient solution; just remember to rough in the PEX tubing on top of panels like Heat-Sheet before you pour!