Introducing Heat-Sheet®

The Advanced Radiant

Floor Panel System

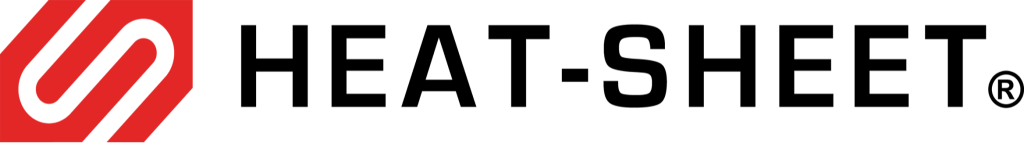

Compact 4’ x 2’ Heat-Sheet radiant floor panels are convenient to stock, easy to install and provide continuous insulation.

Heat-Sheet panels are engineered to save up to 75% of pex pipe installation labor and can eliminate taping and poly.

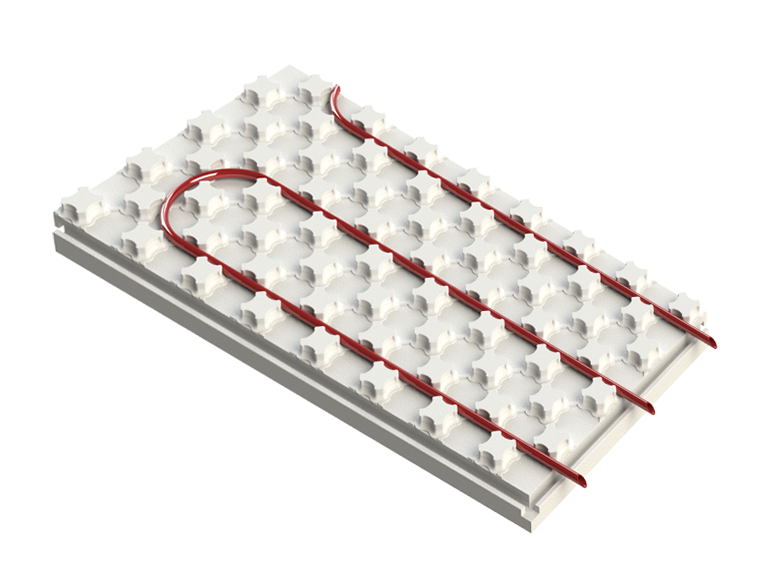

Meet Heat-Sheet®

Heat-Sheet®

R4 - R16.1

Perfectly Designed for Under-Slab,

Slab-On-Grade and Retrofit Applications

Heat-Sheet® Heavy

R8 - R20

Perfectly Designed For Snow-Melt,

Garage and Commercial Heated Floors

EZ 1-2-3 Installation

- Ensure the ground is reasonably level. Install a vapor barrier if required.

- Place Heat-Sheet panels. Interlock the panels together and create a running bond pattern.

- Walk tubing into place. A plastic staple may be required on the turns. Place wire mesh and rebar, if required, on the panels

-

Start pouring concrete: Full installation instructions are available for download.

Dig A Little Deeper

Watch An Introductory Webcast (20 min)

Register For The Next LIVE

Interactive Webcast

- September 20, 2024 11:00 am

- Highly Interactive Online Webcast

Connect

Beaver Plastics Ltd.

Acheson, Alberta

888.453.5961

beaverplastics.com

Beaver Plastics Ltd.

Chilliwack, British Columbia

888.453.5961

beaverplastics.com

AMC Foam Technologies Inc.

Winnipeg, Manitoba

877.789.7622

amcfoam.com

Form Solutions

Cobourg, Ontario

888.706.7709

formsolutions.ca

Form Systems

Wichita, Kansas

888.838.5038

formsystemsinc.com

- Exclusive Content

- Insider Industry News

- Limited Edition Webcasts

Don’t Miss a Thing!

- Exclusive Content

- Insider Industry News

- Limited Edition Webcasts

Request a Quote

Whether you are just starting out or well on your way toward your next big project, we would love to hear from you.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

General Inquiries

Whether you are just starting out or well on your way toward your next big project, we would love to hear from you.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Thank You for Your

Interest in Heat-Sheet!

Request a Quote

Radon Diffusion Applications

Whether you are just starting out or well on your way toward your next big project, we would love to hear from you.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Almost there...

For unlimited access to all of our technical and marketing resources, please enter your information. We will also email you a copy of each of the items you select for quick future reference.

By submitting the form, you agree to our Terms and Conditions and our Privacy Policy. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.