Builders are increasingly understanding the dangers associated with radon. The toxic gas is the #1 cause of lung cancer in non-smokers; it’s invisible; it’s odorless; and it’s surprisingly good at infiltrating homes.

And yet, the industry continues to rely on relatively rudimentary methods, such as a 4-inch gravel layer and a PVC pipe, to diffuse radon in homes that are built to last almost a century.

Luckily, there is now a better, more effective gas permeable layer option than 4 inches of gravel. And recently, this method received validation from the National Research Council of Canada.

In the post below, we’ll explain why Heat-Sheet Heavy outperforms the conventionally used 4-inch gravel as a radon diffusion layer. You’ll also see the NRC testing data that confirms Heat-Sheet’s superior performance.

However, gravel shifts and settles over the years, potentially leaving less and less room through which radon can travel to its escape pipe as time goes by. And given that modern homes are built to last 75-100 years, it’s concerning that such a solution that is likely to degrade over time is still trusted to channel a cancer-causing gas away from human dwellings.

The Increasing Dangers of Radon

Radon is a toxic, cancer-causing gas that occurs naturally in much of North America. And as our homes get more and more airtight, the health risks associated with radon accumulation rise in severity.

Why The Mainstream Solution Falls Short of Offering True Protection

The mainstream solution for radon diffusion beneath concrete slabs consists of a 4-inch gravel layer and a PVC pipe that collects the toxic gas and diverts it away from the home

Heat-Sheet Heavy Offers A Superior Radon Diffusion Solution

Heat-Sheet Heavy offers a superior radon diffusion solution, as it’s far more effective at channeling the toxic gas and because its permeability does not deteriorate over time.

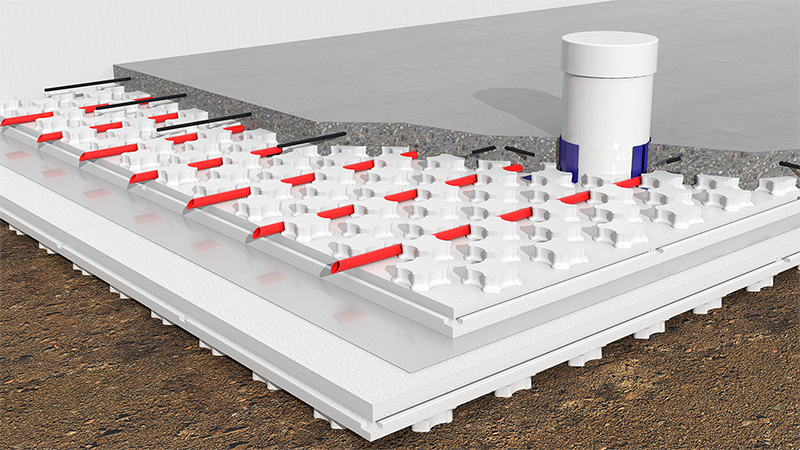

Heat-Sheet Heavy is a rugged, heavy-duty radiant floor heating insulation product that comes with special 1.25” tall nodules for securing PEX tubes.

Unsurprisingly, Heat-Sheet Heavy performs exceptionally well as a gas permeable layer — as long as you install it upside down, with the 1.25” nodules to the underside. The channels that Heat-Sheet’s 1.25” nodules now form create an unobstructed path through which radon can flow toward the collection pipe.

Better yet, Heat-Sheet Heavy does not settle or degrade in any way over time, so there’s no concern that radon will have less room to flow through decades after a home is built (unlike gravel).

National Research Council (NRC) RIBETS Test

Heat-Sheet’s performance as a gas permeable layer has been validated through thorough testing by the National Research Council of Canada.

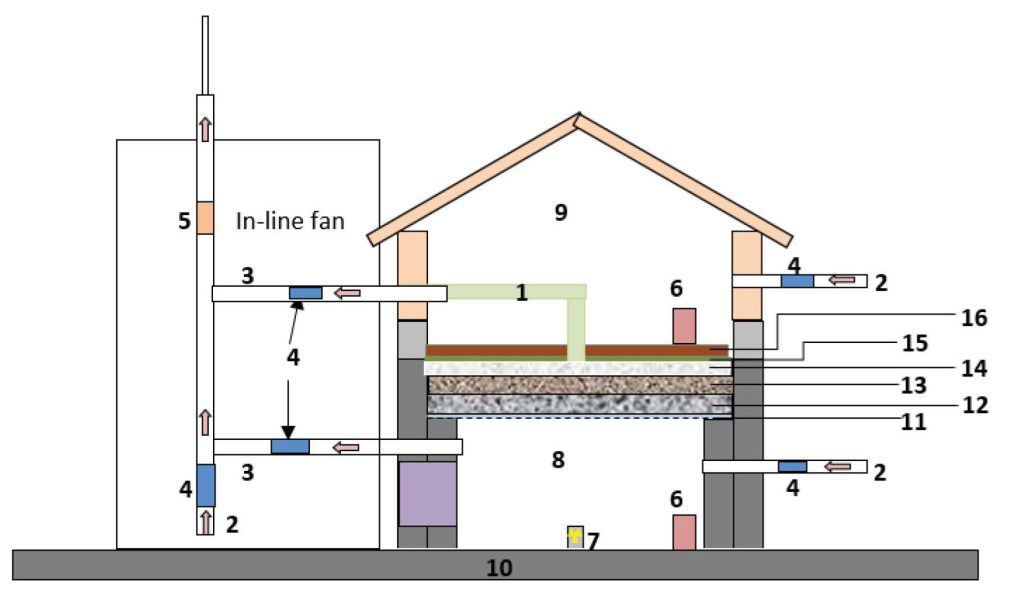

Logix Brands asked Canada’s National Research Council to assess Heat-Sheet Heavy’s ability to effectively diffuse radon in a sub-slab application. NRC is ideally suited for this purpose, since it’s equipped with the specially developed Radon Infiltration Building Envelope Test System (RIBETS) laboratory.

NRC’s RIBETS test compared the radon diffusion performance of the commonly used 4-inch granular layer versus Heat-Sheet Heavy.

The facility used for the comparative analysis consisted of two chambers: the radon dosing chamber (where the gas was deployed) and the radon receiving compartment (where the gas content was measured). The two chambers were separated by a floor assembly, which was constructed differently for the gravel and Heat-Sheet Heavy samples.

Here is what the composition of the floor assembly comprised for each test sample:

Conventional, 4-inch gravel sample:

- 8-inch gravel layer

- 6-inch sand layer

- 4-inch gravel layer

- 6-mil poly membrane

- tape-sealed, varnished wood floor

Heat-Sheet Heavy sample:

- 8-inch gravel layer

- 6-inch sand layer

- Heat-Sheet Heavy layer with nodules facing down

- 6-mil poly membrane

- tape-sealed, varnished wood floor

A PVC stack was installed to collect the radon from beneath the slab, as it would be in a real home. At the same time, two copper pressure taps were fitted to measure air pressure under the diffusion layers and between the air barrier and the wood flooring finish.

During the test, which lasted roughly 2 hours per sample, the in-line radon fan activated the radon stack inside RIBETS, while the researchers analyzed the following data:

- The flow rate within the radon stack

- The pressure in the lower chamber of RIBETS

- The pressure beneath the respective gas permeable layers

- The pressure above the gas permeable layer

The results of the NRC RIBETS test were as follows:

- Conventional, 4-inch gravel gas permeable layer: The in-line radon fan could withdraw air at a rate of 6.42 cfm, leading to a pressure of -2.00 Pa in the gravel layer.

- Heat-Sheet Heavy gas permeable layer: The in-line fan drew air at a flow rate of 9.91 cfm, leading to a pressure of -2.04 Pa in the diffusion layer.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

These results mean that Heat-Sheet Heavy resulted in a 50% improved flow of gas compared to the conventionally used 4-inch gravel layer.

NRC’s test made it obvious that Heat-Sheet Heavy is not only an acceptable solution for radon diffusion — it’s a much better solution than the one commonly employed on construction sites across North America.

Wrapping It Up

The health risks of radon accumulation increase as our homes get more airtight, and it’s time for a solution that’s more robust than 4 inches of gravel and a PVC pipe.

As NRC testing has shown, Heat-Sheet Heavy outperforms the traditional 4-inch gravel layer as a gas permeable layer. (And it insulates the slab from underneath as well!)

Download the Logix Brands Heat Sheet Test Report 2023