Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

If you are a regular reader of any of the Logix Brands blogs, you’ll know we have been talking about how the construction industry is going green and adopting sustainable practices.

To this end, we want to draw your attention to a recent report from the EPS Industry Association found that expanded polystyrene – EPS – recycling is on the rise.

EPS has been a popular insulation material since the 1950s. Now since it has become part of a range of innovative and sustainable products (like Heat-Sheet radiant panels and Logix ICFs), EPS is now a key part of green building design.

EPS Recycling Rate on the Rise

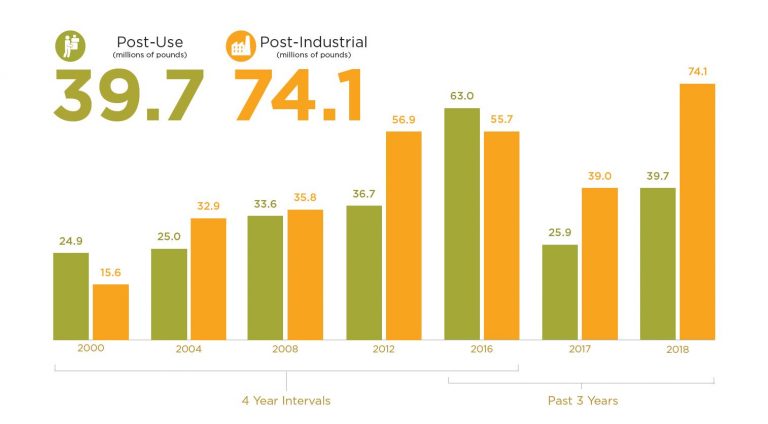

In EPSIA’s 2018 Expanded Polystyrene Recycling Rate study, Canada and the US recycled more than 128 million pounds of EPS. This figure includes 45.9 million pounds of post-use materials (material that is recycled after its intended end-use), as well as 82.7 million pounds of post-industrial recovery (which includes EPS facility scrap that is recycled but never served its intended purpose, often because it is recycled in the manufacturing plant).

To put the above numbers into perspective, this is roughly double the total amount of EPS recycled in the previous year. (Indeed, EPS recycling has seen consistent overall growth since 1991).

What is interesting about the above study is that not only was it voluntary, but it also only reflects the minimum amount of EPS recovered for recycling. Put another way; this number could actually be a lot higher.

Sustainability = Logix Brands

If you’re a builder or homeowner with a more environmentally-conscious focus, EPS is a forward-thinking choice.

First, it’s a highly recyclable product (more on this to come) that is also locally manufactured. But it also generates less waste in general due to its compressive strength potential of up to 40 psi or higher.

This is why many contractors love a product like Heat-Sheet (made with higher density EPS) as its strength means less breakage and waste and ultimately, more time and cost savings on the job site.

EPS also has a minuscule embodied carbon footprint compared to XPS because clean steam is used in its manufacturing process rather than global warming gas-laden blowing agents, which is the case with XPS.

Taking Advantage of Strong Post Use Recycling Service

When it comes to recycling initiatives, Beaver Plastics Ltd., a member of the Logix Brands consortium, is a good example of a company with a strong recycling initiative behind it to reduce waste.

Here’s how Beaver Plastics’ recycling program works:

This is a program that’s a good example of a producer who combines an effective post-industrial recovery program with a vibrant post-use recovery program. To this end, at Beaver, all the trim and scrap pieces that are created are captured and ground-up. The re-grind is then used in the production of new billets, which means that virtually no post-industrial waste is created. On the post-use front, unused materials on various job sites and at various production facilities are bagged and then returned to Beaver’s facility in Edmonton, Alberta.

If the recovered EPS is considered “clean,” it will be re-ground and used in the production of new billets (up to 10 to 20% of EPS billets can be re-grind, depending on the spec). If the recovered EPS is somewhat dirty or contaminated, it gets ground up and then densified and compacted into “logs.” The densified logs then go to third party recyclers who melt the logs down to polystyrene, which is then used to make durable and long-lasting consumer products like picture frames, fencing, and so on.

Wrapping It Up

EPS has been around since the 1950s, but it is now receiving the attention it deserves as an innovative and sustainable construction material.

With its recycling potential, compressive strength, and low embodied carbon footprint, and it’s a clear choice for radiant floor panels like Heat-Sheet and insulated concrete forms like Logix ICF.

Start saving time and money with Heat-Sheet® today! Request a quote, get more information, or talk to a Heat-Sheet® Advisor by contacting us today.

Sources: