Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

Heat-Sheet saves contractors a lot of time compared to the old way of laying PEX pipe over regular flat XPS insulation panels. That’s what contractors love about it.

But that’s not the subject of today’s blog post.

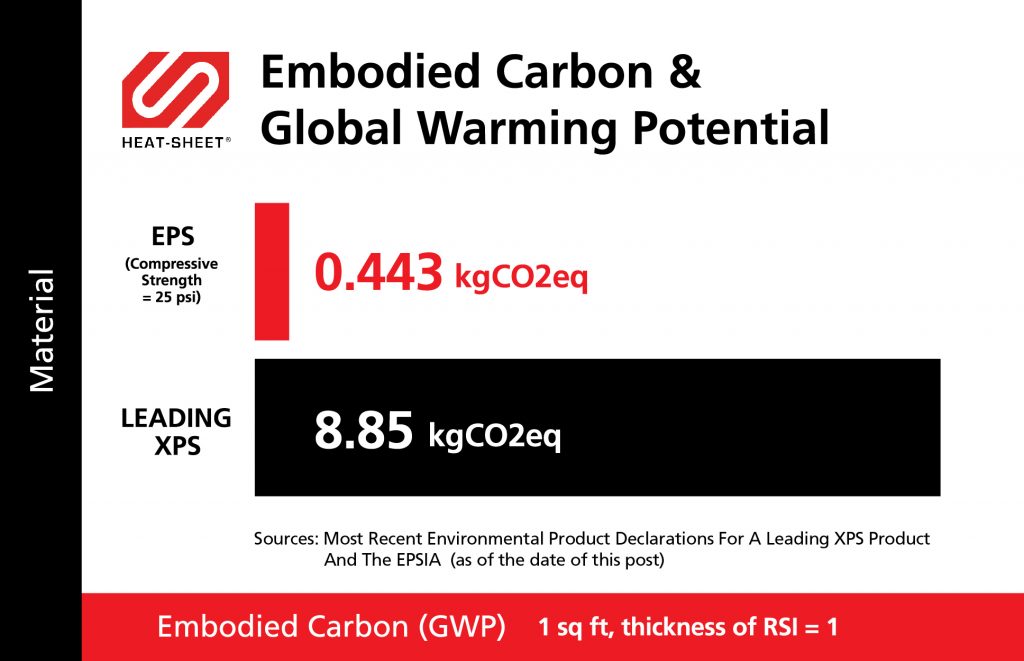

In this article, you’ll see how Heat-Sheet, made with expanded polystyrene (EPS), comes with a tiny fraction of the embodied carbon of extruded polystyrene (XPS) products as well. For builders looking for time savings while lowering carbon dioxide emissions into the atmosphere, Heat-Sheet is a great option.

If an HVAC installer can choose a building product that reduces embodied carbon by 20 times and is lower-priced and reduces labor, the question is, why not?

Heat-Sheet Has 20X Less Embodied Carbon Than A Leading XPS Product

The headline above really says it all. EPS really does have a tiny fraction of the embodied carbon footprint when compared to XPS.

This is primarily because of the blowing agents used to make XPS products. As a result of these blowing agents, such as HFC-134a or HFC-142b, XPS products in North America tend to be filled with greenhouse gases. HFC-134a is actually 1,420 times more harmful to the atmosphere than carbon dioxide. That’s actually a crazy number to comprehend and it’s why this blowing agent is already banned in parts of the world, including parts of the USA and the EU.

And, even worse, HFC-142b is 2,310 times more harmful to the atmosphere than carbon dioxide!

Why Builders Should Choose Products (like Heat-Sheet) with Lower Embodied Carbon

Carbon dioxide is the gas in our atmosphere that controls temperature. Higher levels of carbon gas in the atmosphere results in higher temperatures on earth.

Homes and buildings emit carbon dioxide into the air in two main ways:

- When the building materials used to build the structure are manufactured and when the structure is built (this is called embodied carbon).

- The heating and cooling of the building over time (this is called operating carbon).

Thus builders, designers, and owners looking to minimize the carbon emissions of their homes and buildings should select those building materials that have lower embodied carbon AND contribute to reducing the heating and cooling loads. This is why Heat-Sheet is an excellent overall low carbon choice.

Material choice can make a BIG impact. Using the material examples in the chart above, choosing to place R10 Heat-Sheet under a 1,600 sq ft slab instead of the referenced XPS product will save about 52,000 lbs of embodied carbon. Assuming natural gas as the fuel source, the projected carbon emissions for an average 1,600 sq ft home for heating and cooling in a cold climate is about 8,200 lbs of operating carbon per year. So, in this case, the builder’s simple decision to use Heat-Sheet instead of the XPS product in the slab just saved the equivalent of 6.3 years of the home’s entire operating carbon output for heating and cooling.

Further Recommended Reading

● Read about the efficiencies of Heat-Sheet here.

● More on the sustainability of Expanded Polystyrene here.

Start saving time and money with Heat-Sheet® today! Request a quote, get more information, or speak with a Heat-Sheet® Advisor by contacting us today.

Sources:

https://www.worldgbc.org/sites/default/files/UNEP%20188_GABC_en%20%28web%29.pdf