Jobsites, construction activities, and a building’s live loads can expose products like Heat-Sheet to harsh conditions, especially if heavy loads are applied to the floor. If you’re using Heat-Sheet, you may rightfully wonder just how much load these slender panels can withstand without damage and the resulting waste.

The good news: Heat-Sheet panels with the lowest compressive strength of 25 psi are more than strong enough under most circumstances. And if you expect significant loads, Heat-Sheet has a special product that will have you covered. Read our article below to find out more!

Heat-Sheet 25 psi — More Than Sufficient for Residential Use

Most underslab insulation hits about 20-25 psi, which is actually overkill in residential applications. Heat-Sheet’s lowest available compressive strength — 25 psi — is more than adequate for placement under slabs in residential construction.

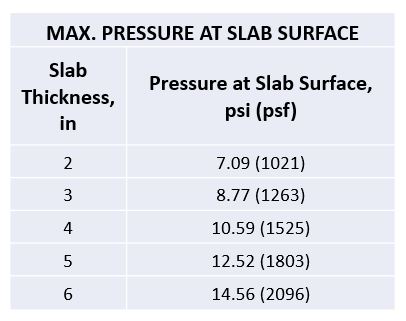

For example, a 6-inch concrete slab will exert 75 pounds per square foot (psf), or 0.52 pounds per square inch (psi) on the Heat-Sheet panel. If you then drive a 10,000lb truck on top of this assembly, the wheel load will add 997 psf, or 6.92 psi — 4 times lower than the 25 psi maximum for which these panels are rated.

With this load, you get <2% deformation, which is well within Heat-Sheet’s elastic limit; meaning, the panel will revert to its normal state without damage once the load is removed.

Of course, exerting 25 psi on a 25 psi-rated panel would cause it to surpass its elastic limit and deform quicker and beyond repair.

So, if you know your projected live loads, you can use this rule of thumb when selecting the compressive strength of your Heat-Sheet product:

If the loads exerted directly on to the slab don’t exceed 35% of the compressive strength of Heat-Sheet, the panels will not deform more than 2.2% over a 50-year period.

This means that it’ll take half a century for a 4-inch thick panel to compress by about 3/32 of an inch at the most.

If you want to reduce long-term deformation in your Heat-Sheet panels even more, you can be a bit more conservative with the loads.

Heat-Sheet Heavy 25-60 PSI — Tough Panels For Commercial, Industrial, and Harsh Job Sites

While Heat-Sheet’s 25-psi panels will serve you well in most circumstances, there are cases when you need more durability on your site.

For instance, if you’re using Heat-Sheet in a snow-melt application and expect tons of heavy equipment rolling over the driveway during construction, it only makes sense to opt for the toughest solution. Same goes for certain commercial and industrial projects, where you can expect the building’s function to result in massive live loads over the Heat-Sheet panels.

That’s why Heat-Sheet offers the Heat-Sheet Heavy series, which can be custom-ordered all the way up to 60 psi.

Heat-Sheet Heavy panels come in widths ranging from 2 ¾ to 4 ⅛ inches, offering thermal resistance of R-8 to R-14/R-16.1, respectively. Since Heat-Sheet Heavy is designed specifically for commercial, industrial, and snow-melt uses, the panels can accommodate all PEX tubing sizes, including the larger, ⅝-inch and ¾-inch diameters. These wider tubes are perfect for heating driveways and broad, open interior spaces like shops and hangars

Wrapping It Up

Heat-Sheet’s regular, 25 psi panels may seem light and slender, but they pack tons of compressive strength that should have you covered in most applications and site conditions. Thanks to their tremendous strength, these panels can withstand heavy live loads without significant deformation, and our table above has shown you how to limit their deformation as much as possible.

But if you’re still concerned that the significant loads you expect from your building — or construction site — may damage the panels, don’t fret. Heat-Sheet Heavy goes all the way up to a compressive strength of 60 psi. That’s more than enough to withstand any reasonable live loads without long-term deformation.