What Determines PEX Tube Sizing?

Getting the tube size right is essential to ensuring occupant comfort and the system’s efficiency. That’s because the diameter of the tube has a direct impact on the hot water flow rate, and consequently the heat output. Tubes with a larger diameter deliver a higher volume of hot water in a given time (flow rate), and thus produce more heat per square foot of the floor than pipes with a smaller diameter.

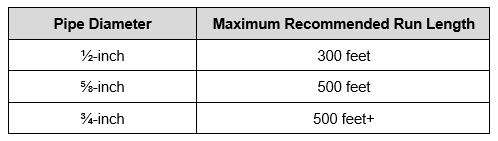

Zeroing in on the correct tube size is also necessary to ensure proper coverage of the room where the heating system will be installed. Smaller tubes with a lower flow rate have a shorter maximum run length, while their higher-capacity, wide-diameter counterparts can extend a bit longer. This means that an exceptionally large space may require a wider tube to accommodate the needed run length and ensure coverage of the entire floor area.

Here’s a brief summary of the correlation between tube diameters and maximum runs:

Other factors that affect heat output include water pressure, temperature, and tube spacing. Tweaking either of these variables can cause the heating system to emit more or less radiant heat, and to work with greater or lower efficiency.

Note that the water temperature will depend on the type of heating system specified for the building. For instance, a heat pump will produce lower flow temperatures than a boiler. To make sure that the radiant floor heating system you’re installing will work efficiently, find out what water temperature you’re dealing with before you arrive at the correct tube diameter and spacing.

Optimal Sizes For Various PEX Pipe Applications

Generally speaking, each pipe diameter size is best suited to a specific application. Well-insulated, smaller spaces can reach desired temperatures with less heat output, and typically require smaller pipe diameters and wider spacing.

Conversely, larger areas, or those that are difficult to heat may need wider pipes that are laid closer together. There are exceptions to these rules; however, the heat output requirement is the principal determiner for sizing.

½-inch Diameter — Ideal For Most Home Applications

The smallest of standard pipe sizes works well for residential applications.

If a home is efficiently insulated and experiences little heat loss, the optimal spacing is 12 inches on center. This spacing produces about 30 BTUs per square foot of the floor, which is enough to keep the room temperature at a comfortable level.

On the other hand, poorly insulated homes lose more heat through their exterior walls, and need an output of at least 50 BTUs per square foot to reach the desired indoor temps. This can be achieved by laying the tubes closer together, at 9 inches on center.

In bathrooms, the optimal temperature is a bit higher than in living or dining areas, so ½-inch diameter tubes may be spaced at 6 inches on center to generate sufficient heat.

⅝-inch Diameter — Optimal Size For Smaller Commercial Spaces

If you need to heat a smaller commercial building or industrial space, the ⅝-inch tube is your best bet. This size also gives you some flexibility with the heat output — all you have to do is tweak the tube spacing.

While only slightly wider than the ½-inch variant, this pipe size allows almost 30% more water volume. The higher flow rate leads to a higher heat output — with a 12-inch spacing, you can get ⅝-inch pipes to produce 50 BTUs per square foot of floor.

This increased heating capacity makes ⅝-inch pipes perfect for small-to-medium commercial spaces. You can even use ⅝-inch tubing in poorly insulated areas, like shops or hangars. While 12-inch spacing is standard, grouping the tubes closer, at 6 inches, can boost the heat output to 150 BTUs per square foot. Conversely, 15 or 16-inch spacing may be more economical for commercial buildings in warmer climates, where the heat out per ft2 can drop below 30 BTUs.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

¾-inch Diameter — Standard For Large Commercial and Industrial Spaces

This is the widest pipe diameter, best suited for large commercial and industrial buildings, as well as snow melt applications.

The ¾-inch tubes double the flow rate of their ½-inch peers and can produce a whopping 150 BTUs per square foot even when spaced at 12 inches on center. With this much heat capacity, ¾-inch tubes work perfectly in more expansive spaces. With this same spacing and heat output, you can also use ¾-inch pipes beneath driveways and walkways to melt accumulating snow and ice.

Wrapping It Up

Establishing the correct tube size is instrumental to having a radiant heat flooring system that works efficiently. While there are many other variables in play, getting the right tube diameter means getting the right water flow rate and heat output per square foot of floor. To recap, here are the ideal applications for each standard tube diameter:

- ½ — residential

- ⅝ — small commercial and industrial

- ¾ — large commercial, industrial, and snow melt

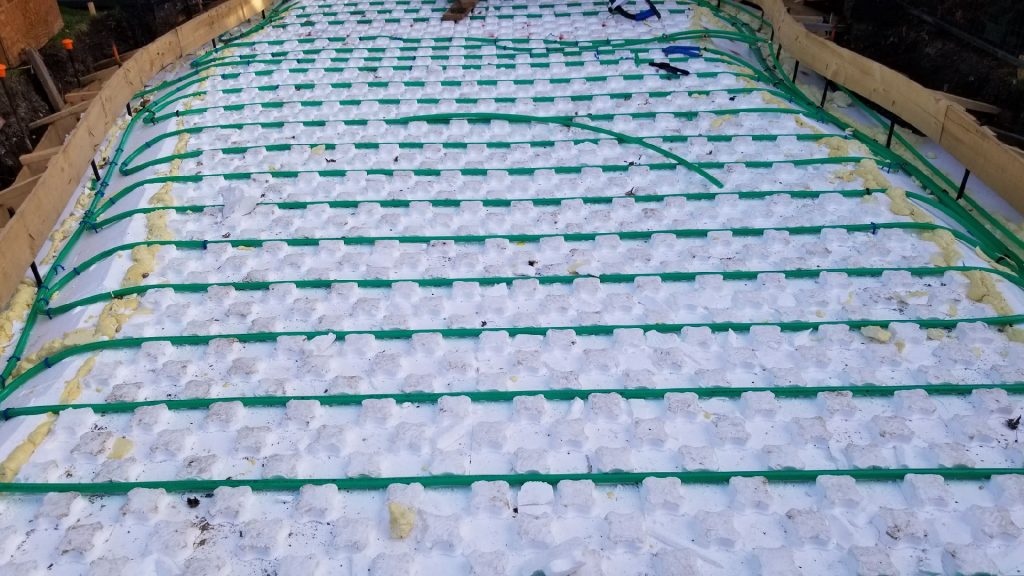

Heat-Sheet’s selection of radiant heat flooring panels includes boards that support these tubing sizes and allow various spacing and orientation options for installing PEX tubing. Best of all, Heat-Sheet eliminates the need to staple tubes down to the boards (except for bends) and makes installation easy and cost-efficient. You can learn about Heat-Sheet’s line of products here.