To be effective, under-slab heating requires adequate insulation to stop downward heat flow. These insulation requirements range by climate zone and can often be pretty demanding.

This post will examine the most common R-Value standards for heated slabs in North America and discuss a range of straightforward solutions that will help you meet the code.

Thermal Resistance Requirements for Heated Slabs

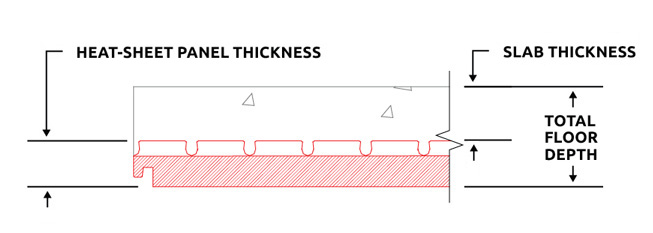

Underslab heating will only work as designed if the heat radiates up through the concrete and doesn’t escape downward towards the cooler soil. As heat typically transfers from hot to cold, this can be achieved by placing the under-slab heating tubes on top of an insulation layer like Heat-Sheet.

To ensure that the insulation has adequate thermal resistance, jurisdictions across North America have various R-value requirements for heated slab insulation.

For instance, heated slabs in Canada require R-13 to R-16 if they’re below grade, while slab-on-grade requirements range from R-11 to R-21, depending on the climate zone. On the other hand, in Ontario, the under-slab insulation needs to hit only R-10.

In the US, the R-Value requirements are a bit less demanding. Heated, unheated, below-grade, and slabs-on-grade must have 2 feet of R-10 insulation along the perimeter in US Climate Zones 4+. That said, this provision can vary quite a bit between cities and counties, so make sure you’re following your locally adapted versions of the building code.

Heat-Sheet® Offers An Industry-Leading Range Of R-Values

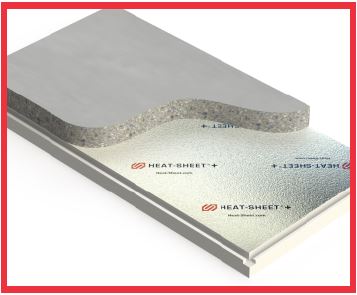

Heat-Sheet® is a cost-efficient solution for insulating heating slabs with hydronic heating systems.

It provides an effective insulation layer and is designed to make tubing installation fast and straightforward.

Unlike many other radiant floor panel systems, Heat-Sheet’s product line offers a wide range of R-Values that can help you meet virtually any code requirement or energy efficiency target. This is one of the unique advantages of the Heat-Sheet product line.

Currently, Heat-Sheet panels are available in stock thicknesses of R-6, R-8, R-10, R-12, and R-14; you’ll have no problems getting these from most distributors in the US and Canada.

If your local code — or client — demands more thermal resistance under the slab, you can also custom-order Heat-Sheet panels with up to these R-Values from several manufacturers:

From Form Solutions — up to R-27.3 in EPS (6 inch thick panels, plus nodules)

From AMC Foam — up to R-36 in EPS, or R-40 in GPS (8 inch panels plus nodules)

From Beaver Plastics — up to R-16.1 in Graphite Polystyrene (GPS) (3 inch thick panels, plus nodules)

From Form Systems — up to R14 in EPS (3 inch thick panels, plus nodules)

With these R-Values, you should have no issues hitting the most stringent code requirements and energy-efficiency targets in any North American climate zone!

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

The Thickest Heat-Sheet Under Slab Application So Far (with Heat-Sheet HD)

Though this was an unheated slab, Chris Bosiak of Bosiak Construction in Stirling, Ontario, opted for 2 layers of Heat-Sheet HD in a passive house he was building. With this build-up, Chris achieved a total panel thickness of 8 inches and R-32.

His crews loved working with Heat-Sheet HD, as the small, interlocking panels were perfect for floating on a compacted surface and made installation a breeze.

Heat-Sheet HD is somewhat unique, as it doesn’t have the familiar nodules that would hold the PEX tubing.

That said, the 2×4, 4-inch panels come in stock 2-inch and 2.5-inch thicknesses but can be custom made to 4 inches, which gets you to R-16 in EPS.

Note that Form Solutions is the sole manufacturer of Heat-Sheet HD, so you’ll only find these panels in Eastern Canada, as well as North- and South-Eastern US.

Wrapping It Up

Heat-Sheet’s line of radiant floor panels offers a massive assortment of R-Values, compressive strengths, nodule sizes, and profiles for under-slab applications.