We originally developed our low profile R4 Heat-Panels for retrofit applications in which preserving ceiling height is a top priority.

But what if we told you that these same slender boards found a surprising high-impact application in a brand-new mid-rise multi-family build?

In this post, we will see how one man’s creative thinking and a willingness to push the envelope pulled a large hydronic radiant floor heating (RFH) installation from the brink of a quality nightmare as well as possible schedule delays and cost overruns.

Our story starts in Burnaby, BC, at the site of the New Vista Care Home – a 7-story building with 240 residential care units. The concrete structure had been designed, and the team met to discuss the installation of heating systems. Being a seniors’ care facility, continuity of service regarding space conditioning was paramount, and so RFH was the cited heating strategy.

Present at this meeting was Chris Gray, the president of Connelly Mechanical Systems Ltd, a full-service mechanical and plumbing company specializing in multi-family residences, seniors’ care homes, and commercial buildings.

As a rule, Chris likes to get involved early in the design stage, when coordination between disciplines has the most impact on making the design efficient, constructible, and error-free. With the New Vista project, the structure had already been designed when Chris and his team were invited to collaborate.

Now, as the meeting spelled out the details of the RFH install, Chris saw that the spec’d approach was a potential HVAC installation disaster in the making.

Relying on ASHRAE 90.1 and CSA-B214, building code mandates that all major occupancies exceeding three stories in height, or 600 m2 in gross floor area, must achieve R-3.5 in floors that are radiant heated. This requirement applies to floor assemblies that separate two habitable spaces, as they do at the New Vista building.

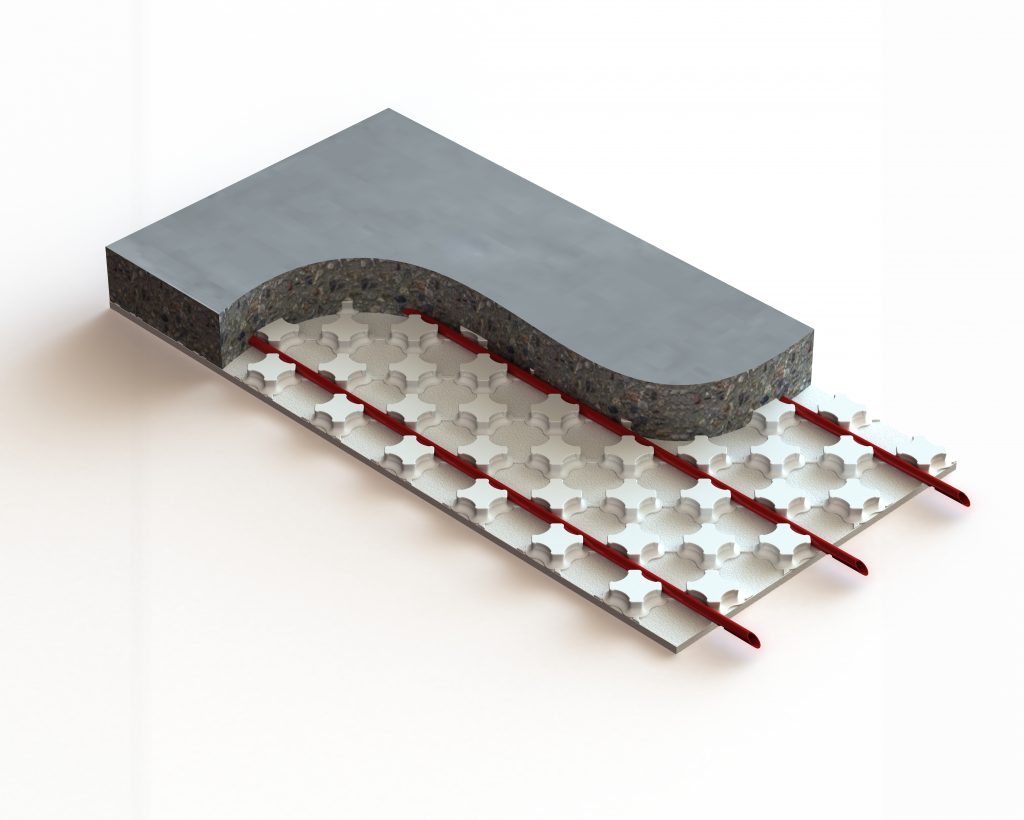

The undersides of the slabs were to be paint-finished, so to comply with the building’s design called for a 1-inch XPS board laid over the top of the 7.5-inch slab, with radiant tubing, then stapled on top.

As he learned these design intentions, Chris knew right away that the 1-inch XPS board would be way too flimsy to secure the staples holding the tubing in place, especially with the way the tubing had to be coiled.

He also feared that the setup process would be extremely time-consuming and tedious. Hoping to avert an expensive quality control issue, Chris quickly got on his mobile browser in search of alternatives. There had to be something sturdier for this application than a 1-inch XPS board.

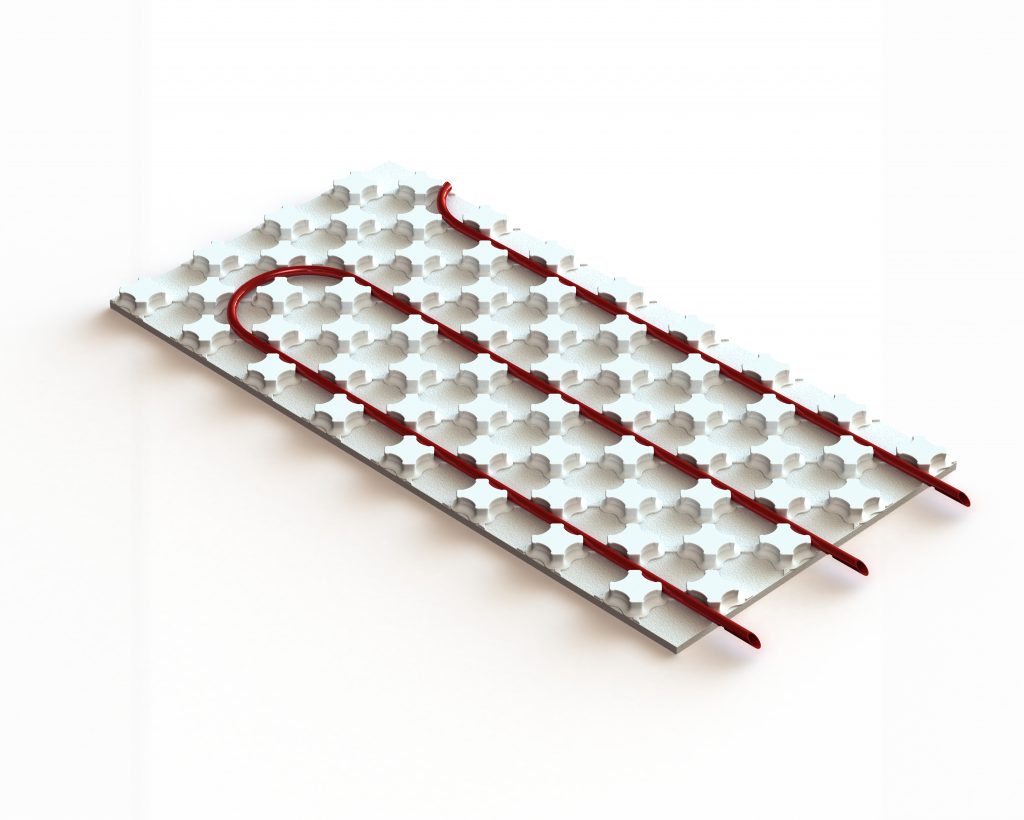

What Chris stumbled on was a fresh solution he had never used before: Heat-Sheet’s low-profile, R-4 panel.

He knew that the lower profile would be perfect for the application, and the thermal resistance would be more than compliant with the code requirements. With this alternative in mind, Chris still had lots to do before the substitution could be tabled and approved.

Because Chris had never worked with Heat-Sheet, he set about testing various densities of the R-4 panel to find the most suitable density for this specific application.

Beaver Plastics, the regional manufacturer, offered Chris invaluable help by supplying samples and consulting on panel densities. With Beaver’s help, and after field testing numerous variations, Chris established that the 40-psi was perfect for this use. Now, he just had to choose the right adhesive to bond the EPS-based Heat-Sheet panels to the concrete.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

After field-testing 12 varieties, Chris found that the “Great Stuff” wall and floor polyurethane foam adhesive worked best. Finally, Chris had a complete solution in his pocket.

After getting the substitution approved, Chris asked the insulation contractor to transfer the scope to Connelly Mechanical Systems. To further optimize the installation, Chris then mapped out the panel layout, making sure that the long seams of the panels run perpendicular to the pipe runs.

With this attention to detail and with the panels in place, pipe installation was a cakewalk – there was no need to spend precious man-hours on stapling the stubborn tubes to a flimsy board. Instead, Chris’ crews simply walked the tubes into place, then topped them off with 2 inches of self-leveling concrete.

In the end, a potentially disastrous design shortcoming was identified and changed in time to avert major quality issues and labor costs for the whole project team.

What’s more, as the Heat-Sheet panels were stronger than 25 PSI and had more than 1 1/4 inches of concrete cover, the conditions of the non-cracking warranty were met.

When the next opportunity arises, Chris will use Heat-Sheet again. As a dedicated and detail-driven HVAC professional, Chris does not impress easily. But Heat-Sheet has earned its place in his repertoire of innovative and cost-effective solutions.

Wrapping it up

As our case study shows, with creativity and hard work, a quality product can really shine in new applications. Heat-Sheet’s R-4, mostly used in residential retrofits and overlays, turned out to be a life ring alternative to the 1-inch XPS.